Introduction to the World of Reverse Engineering

In modern conditions, reverse engineering has become a key solution for the reproduction of outdated systems. This process, representing itself as a detailed study and recreation of existing mechanical and electronic systems, is especially valuable in the context of ancient pump mechanisms, which have already not been produced. According to statistics, about 60% of large industrial enterprises face the impossibility of acquiring necessary spare parts for outdated equipment and reverse engineering provides a unique solution to this problem. Learn more about pump repair services and their application in modern production.

Stages of Reverse Engineering: Detailed Guide

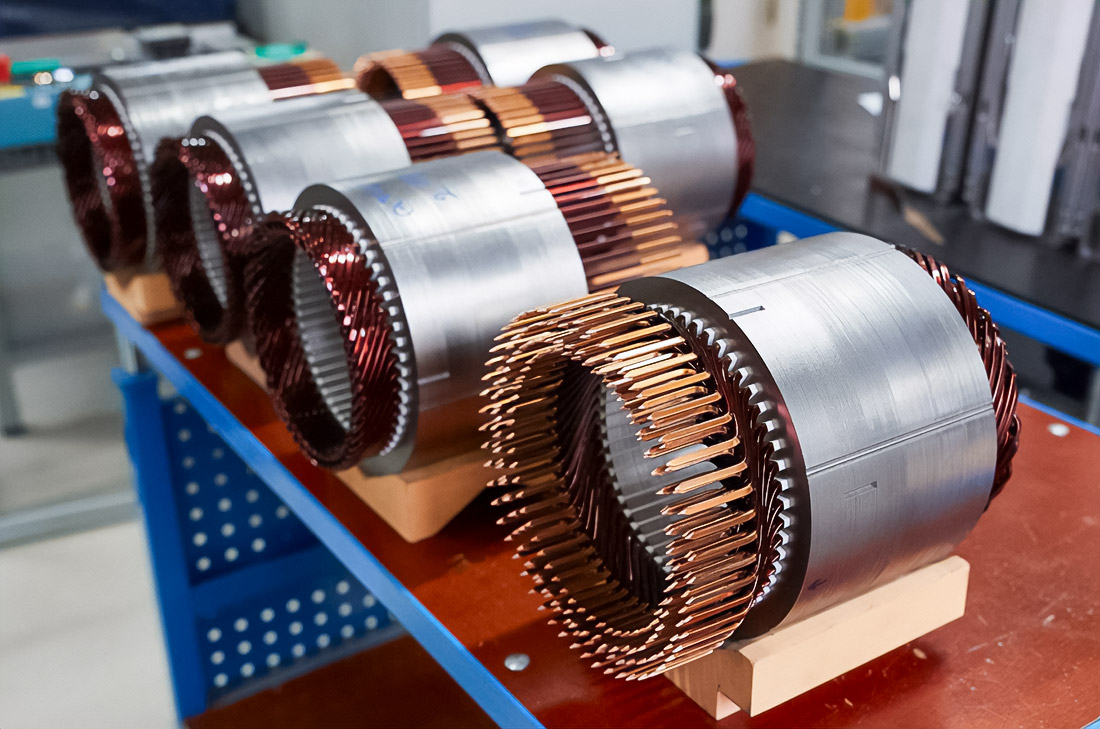

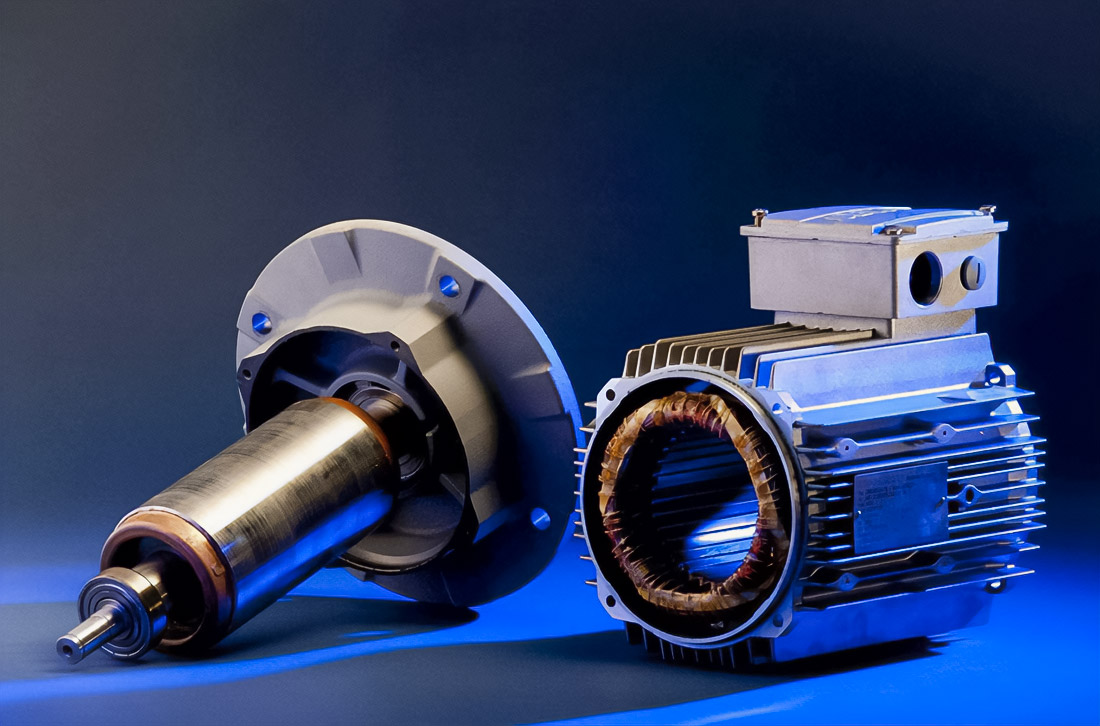

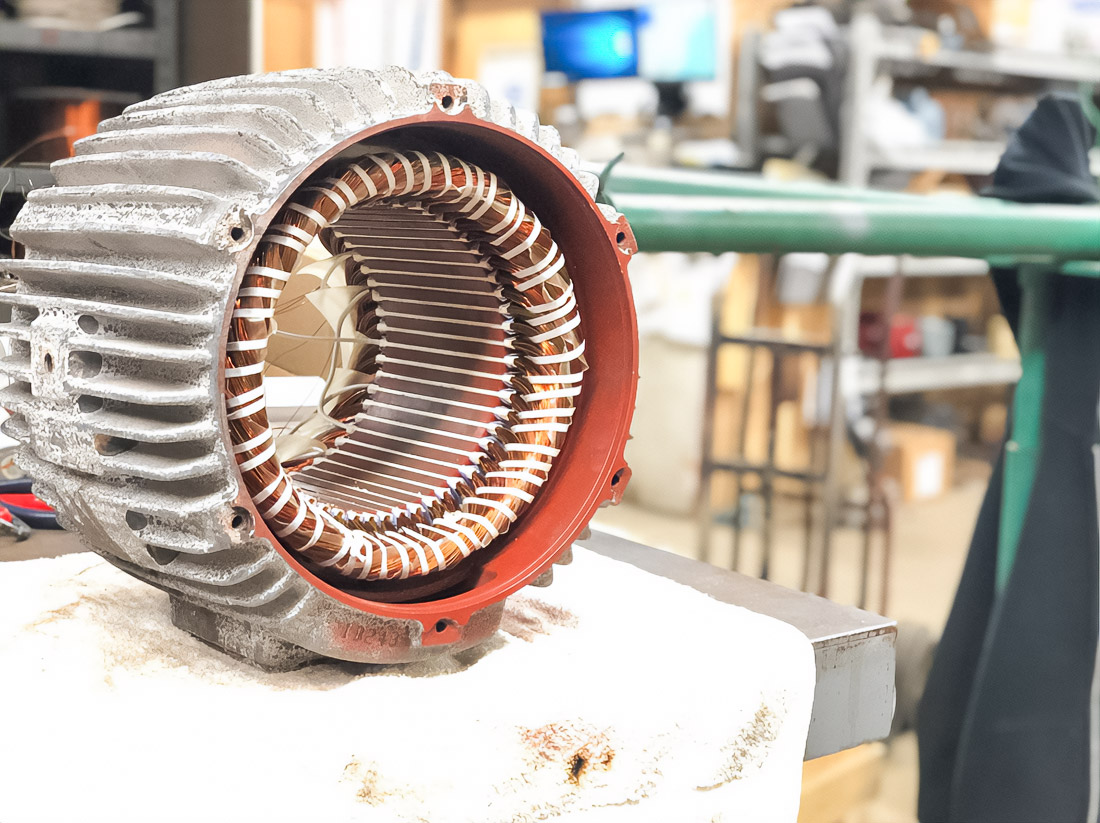

- Detailed Inspection and Analysis: Initial stage consists in detailed inspection of existing systems. The process begins with the dismantling of equipment. Engineers conduct exhaustive research, collecting data about each component. Methods of spectral analysis are used to determine materials, such as laser interferometry, which guarantees the accuracy of measurements to the micrometer.

- Manufacturing Engineering Models and Drawings: At this point, the newest software, including SolidWorks and AutoCAD, is used. 3D scanning is utilized to achieve precise modeling. Digital models allowed the design to be done on a scale with an accuracy of 0.1%. This stage enables the discovery and application of creative enhancements.

- Production of Contemporary Components: At the last stage, new parts are produced. The selection of materials, such as high-strength alloys, depends on their ability to withstand wear and corrosion. Contemporary technologies, such as 3D printing and laser cutting, eliminate waste by 50% and production time by 30%.

Advantages of Reverse Engineering in Industry

- Reduction of Financial Costs: Thanks to the reproduction of parts, enterprises save up to 70% of the cost of complete replacement of equipment. Examples of successful cases include the restoration of uninterrupted operation of production lines, which saved millions of dollars on the purchase of new systems.

- Extension of Equipment Life Cycle: Replacement of critically important elements allows an increase in the lifespan of pump systems by 10-15 years. In some cases, modernized systems operate 20% more efficiently.

- Minimization of Downtime: Quick reprocessing reduces equipment downtime by 40%, ensuring fulfillment of production targets and preventing losses.

Success Stories: Real Life Examples

In the oil and gas industry, successful examples of reverse engineering include the modernization of pump units on fields in the North Sea. Due to this, equipment productivity increased by 25%, and operational expenses decreased by 15%. Also, a company in Australia developed a unique pump mechanism, which increased the wear resistance of parts.

Difficulties and Limitations: Overcoming Problems on Path to Success

- High Complexity of Technical Processes: Some systems are extremely complex for reproduction without loss of functionality. Required engineering team with a high level of qualification.

- Legal Aspects and Intellectual Property: Necessary consideration of possible patent restrictions when reproducing patented technologies. More about this can be learned in intellectual property.

- Quality of Original Materials: Determination of the composition of original materials is a challenge, which can affect the durability of new parts.

Building Successful Strategy: Choice of Tools and Technologies

A range of technologies and the integration of specialized tools must be considered while undertaking reverse engineering. Modeling accuracy is greatly increased by using 3D scanners. For one-of-a-kind projects, additive manufacturing’s unparalleled flexibility and execution speed are vital. The competency of engineering staff should be taken into consideration, and ongoing training should be guaranteed. Learn more about 3D scanning and its application in engineering.

To sum up, reverse engineering is still a valuable tool for businesses looking to cut expenses and update their manufacturing processes. Outdated systems can now be used in innovative ways, turning them from a liability into a competitive advantage.

Hockey fan, nature enthusiast, hiphop head, Eames fan and HTML5 Guru. Doing at the junction of aesthetics and programing to create great work for living breathing human beings. I work with Fortune 500 companies and startups.