As the owner of a factory or an industrial plant or manufacturing unit in Dubai, you might already be well aware of the importance of a grinder wheel. It is useful not just for cutting metals but for an array of other uses. It is used in the automobile industry, woodwork factories, heavy machinery engineering plants, etc. regularly to run operations. Developing an understanding of the different types of angle grinder wheels will help you in deciding the categories you would need for your plant. The short blog here gives you some basic guidelines in this regard.

Grinding Disc

It is one of the most popular types of grinders. It can easily be found in almost all kinds of industrial units. The equipment has a rougher appearance and it has a wind range of grits available. It also tends to produce more sparks when functioning. The tool is available in a number of different sizes. It can be used to prepare pieces of metal for welding.

Cut-Off Disc

Inarguably, this is the second most popular grinder used in several different manufacturing plants and factories. The tool ensures accurate cuts. However, it needs to be mentioned that when you are working with such a disc you need to be extremely careful. In this case, using top-grade safety gear is recommended.

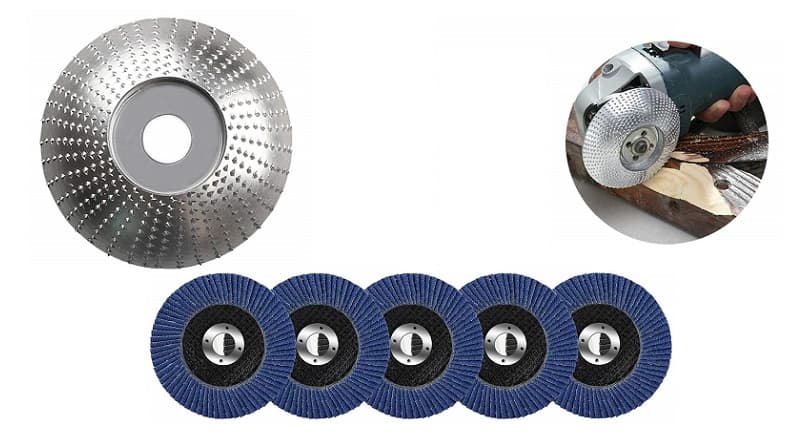

Flap Disc

A grinding disc and a flap disc are quite similar but there is one major difference. The flap disc, as the name suggests, uses a flap to attain a flawless finish. It will also help you in achieving a smoother finish. These discs are also available in a variety of grits.

Wire Wheels

The wire wheels are equipment that has a circle-shaped base and wires are strategically placed around it. Thicker bristles of the wire ensure faster processing of the task. However, if you need to perform a finer task, then using a wire wheel that has thinner, and straighter bristles is recommended.

Diamond Cutting Disc

As the name suggests, these are the sharpest tools available in the competitive market. There should not be any doubt about it. There are diamonds fixed expertly on the surfaces of the rims. Such discs are immensely efficient. They also possess the ability to be abrasion-resistant. The tool can be used for both dry and wet cutting.

Polishing Pads

The significance of polishing pads cannot be denied especially if you plan on imparting a smooth and flawless finish to your task after dealing with an angular grinder. It is easy to use as attaching the pad to the tool can be done quite conveniently. The task becomes more manageable.

Get the Tools from a Renowned Supplier

In case you are on the lookout for the perfect grinder wheels, it is sensible to check out the inventory of a Trusted machine tool supply. You can rest assured that you will find the device that you have been searching for.

Hockey fan, nature enthusiast, hiphop head, Eames fan and HTML5 Guru. Doing at the junction of aesthetics and programing to create great work for living breathing human beings. I work with Fortune 500 companies and startups.